“ShanghaiLithium Carbonate and LIB Cathode Materials Conference”

LMFP Technology Innovation Drives NMC Applicationon the Bus

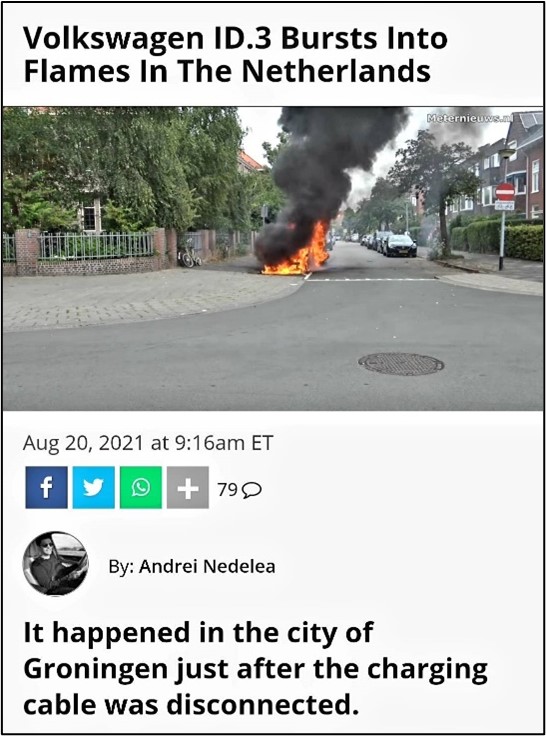

At the beginning of 2016, public information showed that the Ministry of Industry and Information Technologywill make the risk assessment of the lithium battery. Before the assessment is completed, the NMC lithium battery bus will be temporarilysuspended from listing on the catalogue of recommended models for promotion and application of new energy vehicles

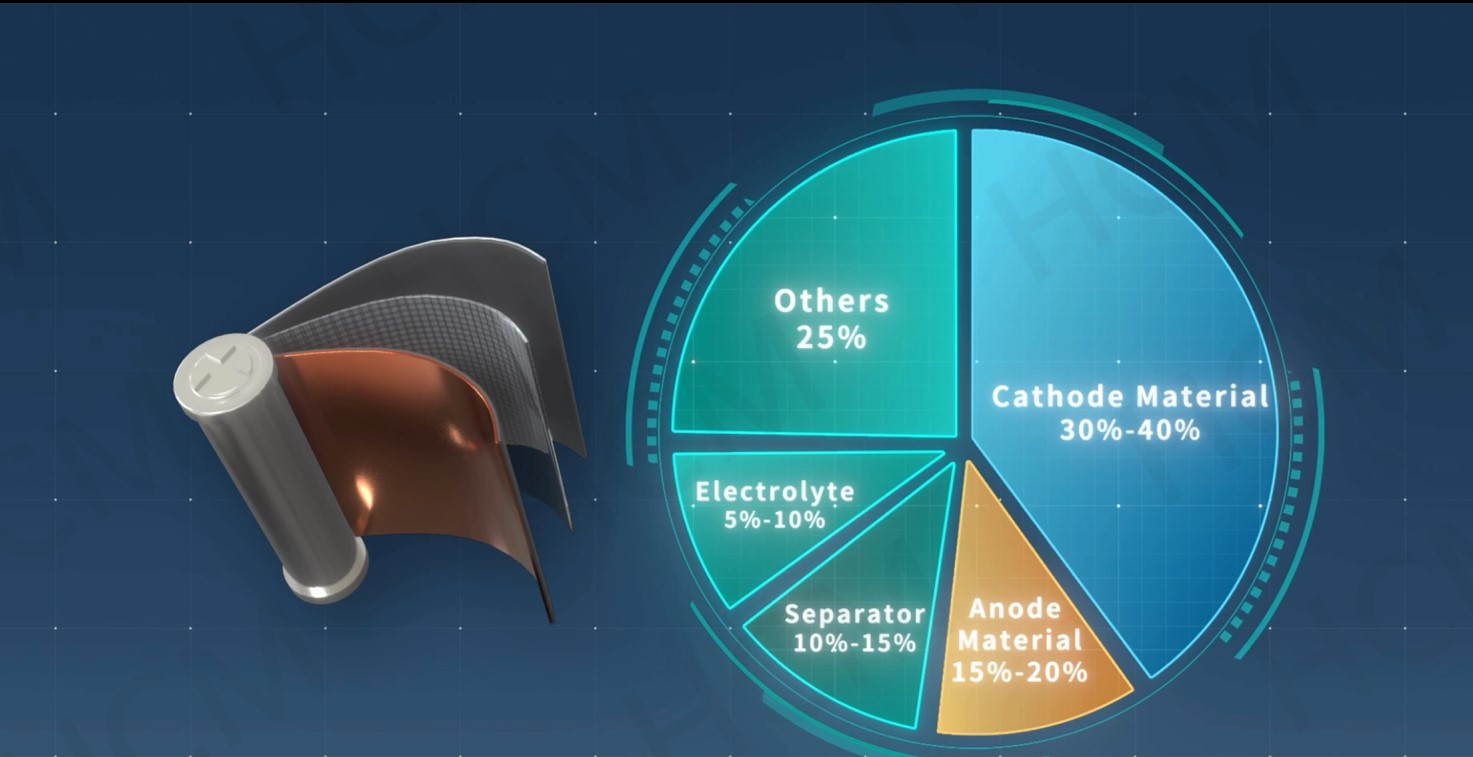

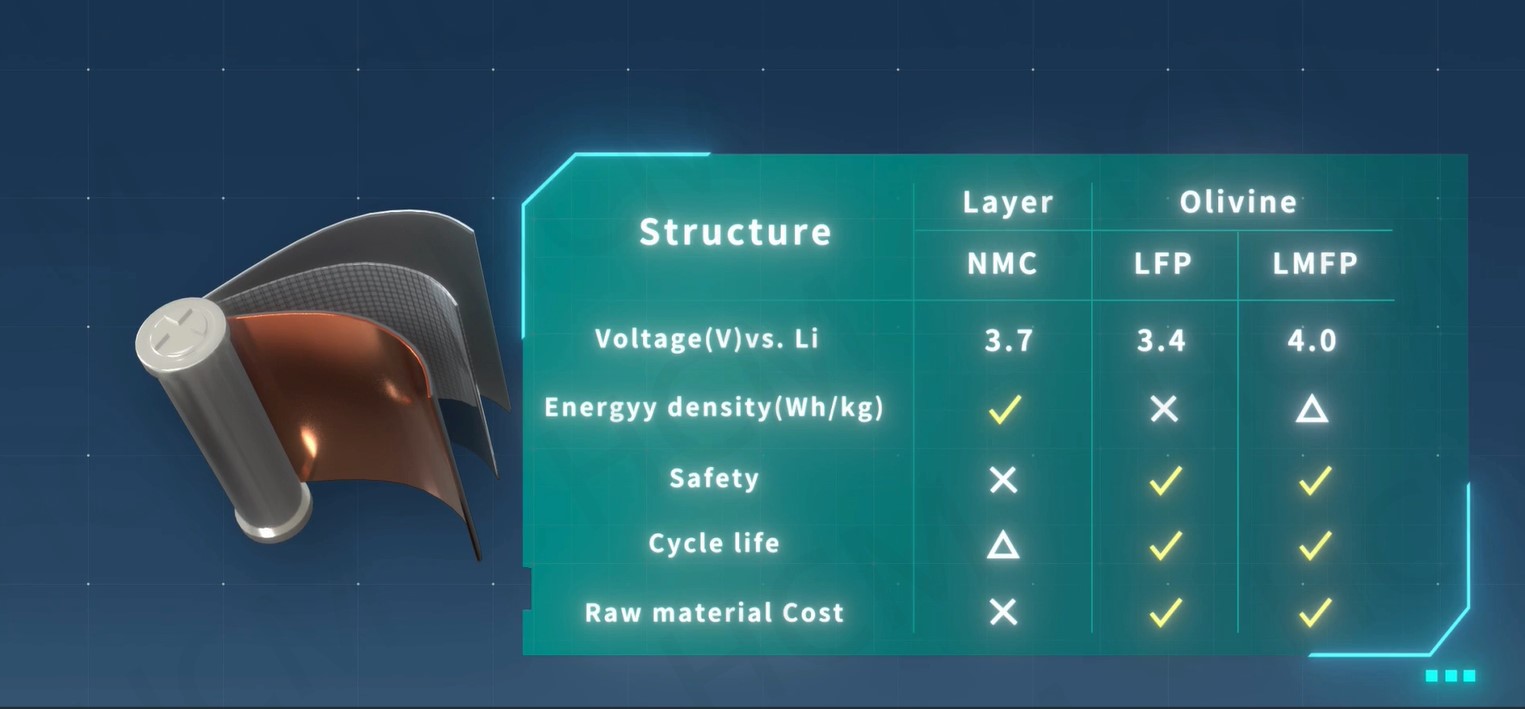

Compared with the LFP battery, the NMC battery has a high energy density, so it has a longer endurance and better low temperature performance. However, NMC react faster than LFP in the event of fire. For buses with more passengers in general, it takes longer time to evacuate. Once an accident occurs, it may cause serious consequences.

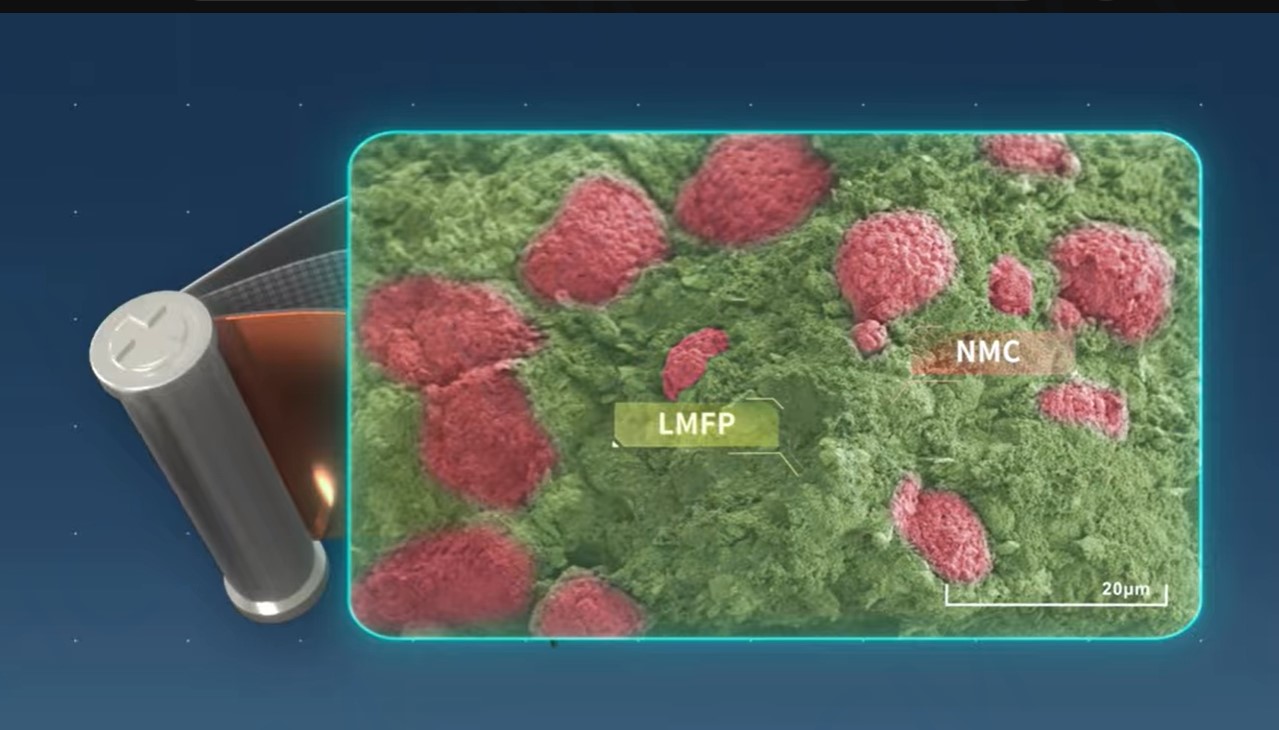

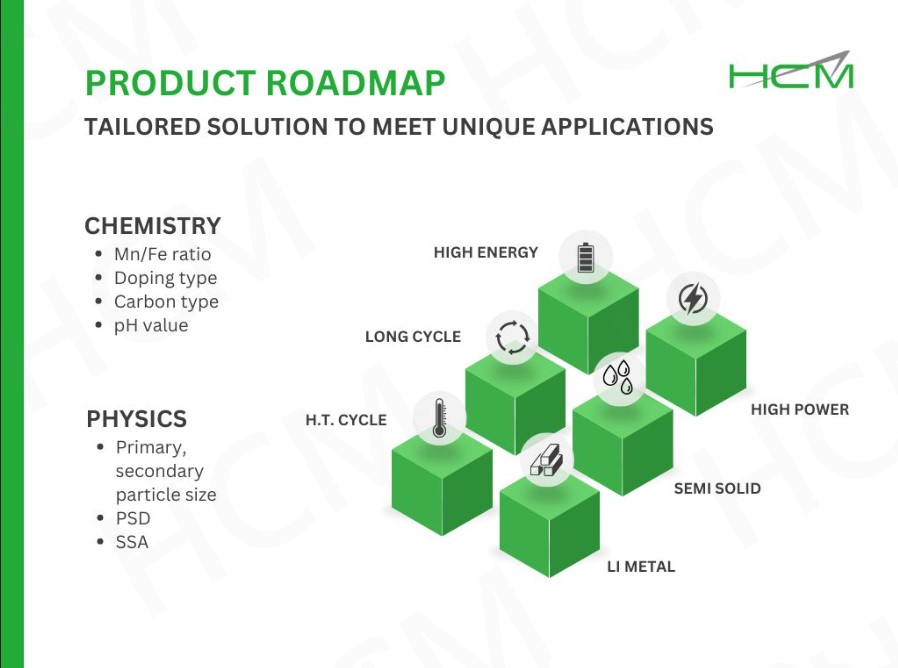

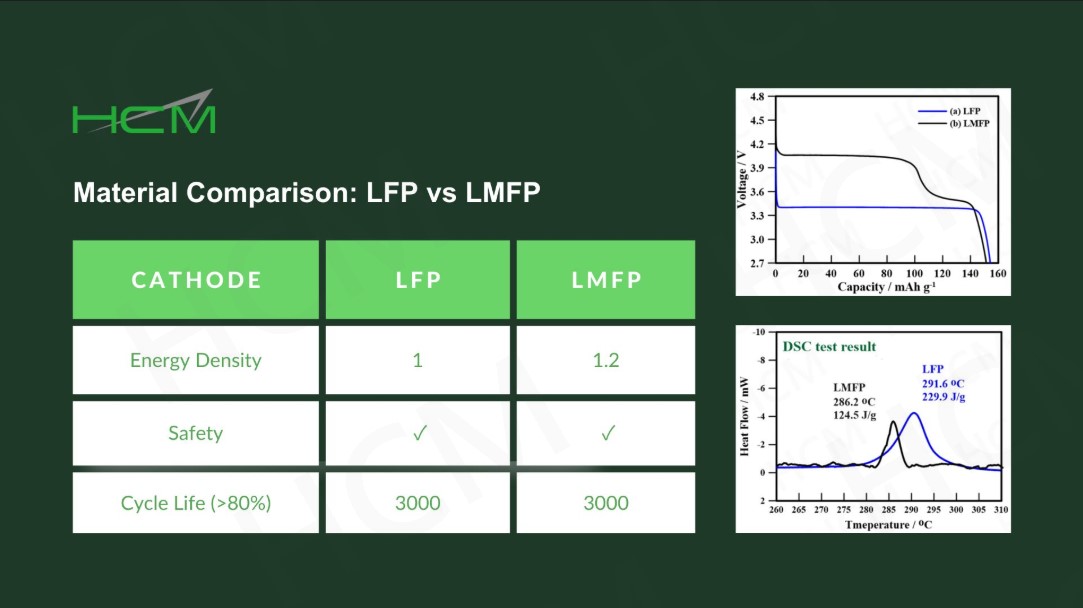

Industry experts said that the combination of LMFP and NMC helps to optimize the safety of NMC and makes it more feasible to apply NMC batteries to buses. LMFP cathode material has smaller particles and can be filled in larger particlesof the NMC gaps to increase the bulk density of the cathode material.The good thermal stability of phosphate can improve the safety of NMC. LMFP Li+/Li electrode voltage is 4.1V, and the high potential is favorable for mixing with NMC that also have the same high potential. It also has a higher energy density than LFP.

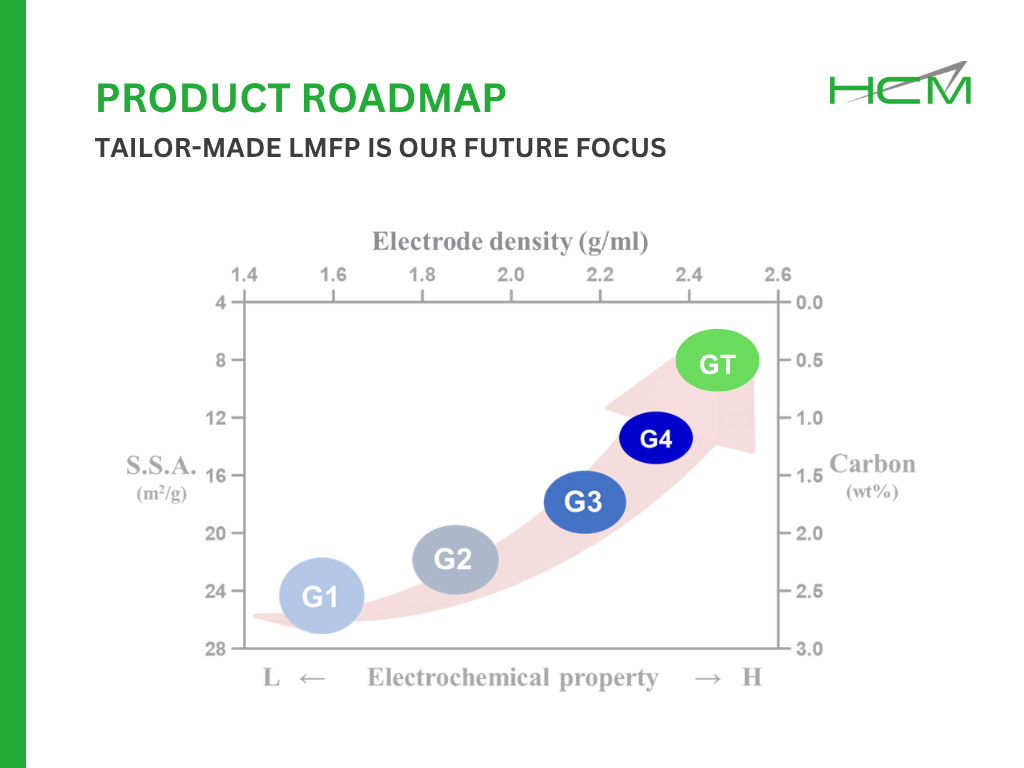

LMFP is considered to be the most promising material for upgrading and replacing LFP.BYD Companyannounced in 2014 that it planned to put LMFP into mass production and applied it to BYD's self-produced vehicles.However, early production and application of LMFP, it encountered difficulties in material synthesis,making electrode plate and small compaction density and tap densityand other problems. The problems need to be solved by enhancing the performance of LMFP by technical innovation.

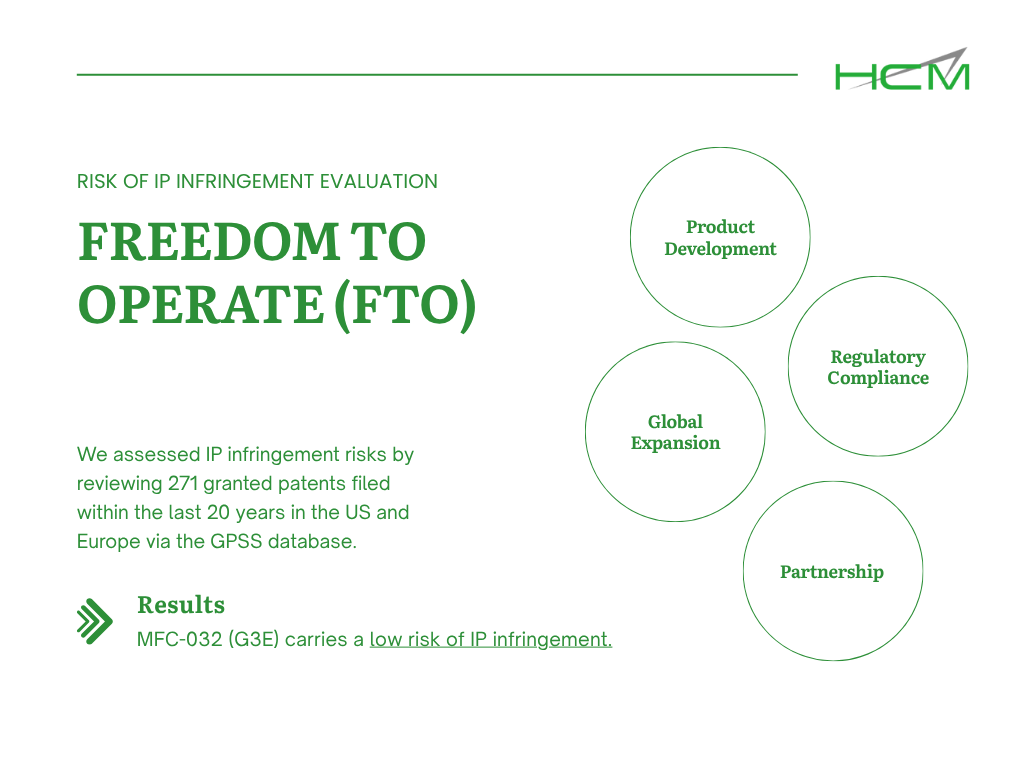

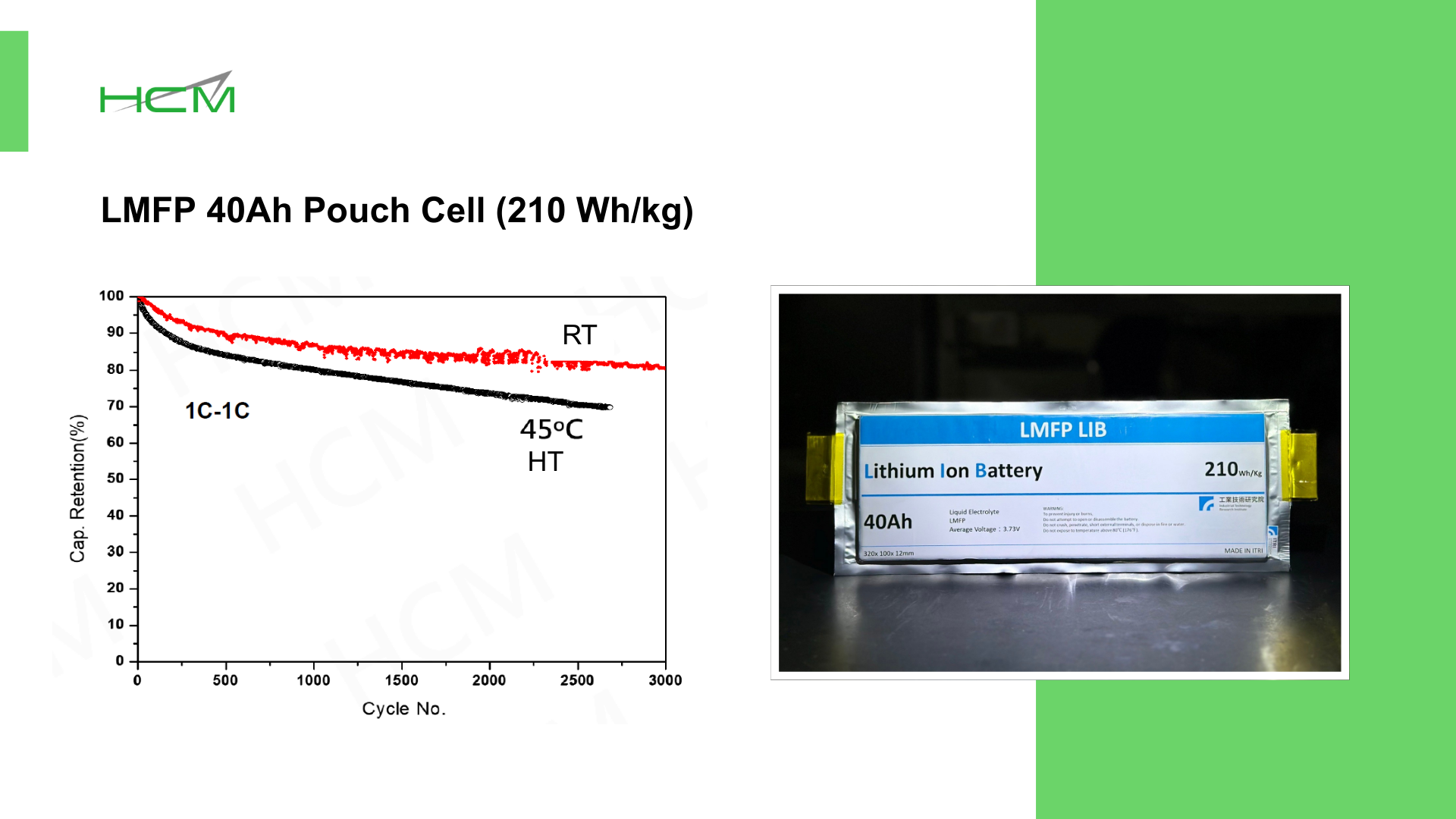

HCM (former Hirose Tech Co., Ltd) developed advanced LMFPmaterials, which have already been put into mass production and sent to lithium battery manufacturers for long-term trials and have already shipped to several manufacturers. HCM has continued to upgrade its LMFP material technology and plans to expand its production capacity.

Industry experts said that in addition to the use LMFP with NMC, batteries made with advanced LMFPmaterials used in the ISS are also promising because of their high energy density and excellent low-temperature performance.

The 2016 “Lithium Carbonate and LIB Cathode Materials Conference”will be held in Shanghai on April 19.The conference will discuss the national new energy automotive industry policy trends, global and China lithium resource distribution, supply and demand and price forecast, China's ore and salt lake brine lithium carbonate project progress, the technical requirements of the battery cathode material, LFP, NMC performance optimization and application, next-generation lithium-ion cathode materials technology outlook and so on.Leading experts from HCM will introduce “LMFP materials and battery technology”.